Production process manual#

For example, a carpenter who creates custom furniture from reclaimed wood might use manual machining to cut, fashion and sand products. Job shops often use manual machining when they create custom products for their clients.

These might be power saws, drills, blowtorches or other equipment requiring training and safety protocols. In manual machining processes, skilled employees operate manual power tools to create products. An example of fully manual manufacturing might be a small farm that harvests and jars honey from beehives kept on the property. Currently, there are few companies that use fully manual manufacturing processes. In this process, facility employees create each product by hand, using specialized implements and skills. Manual manufacturing processes don't involve any level of automation.

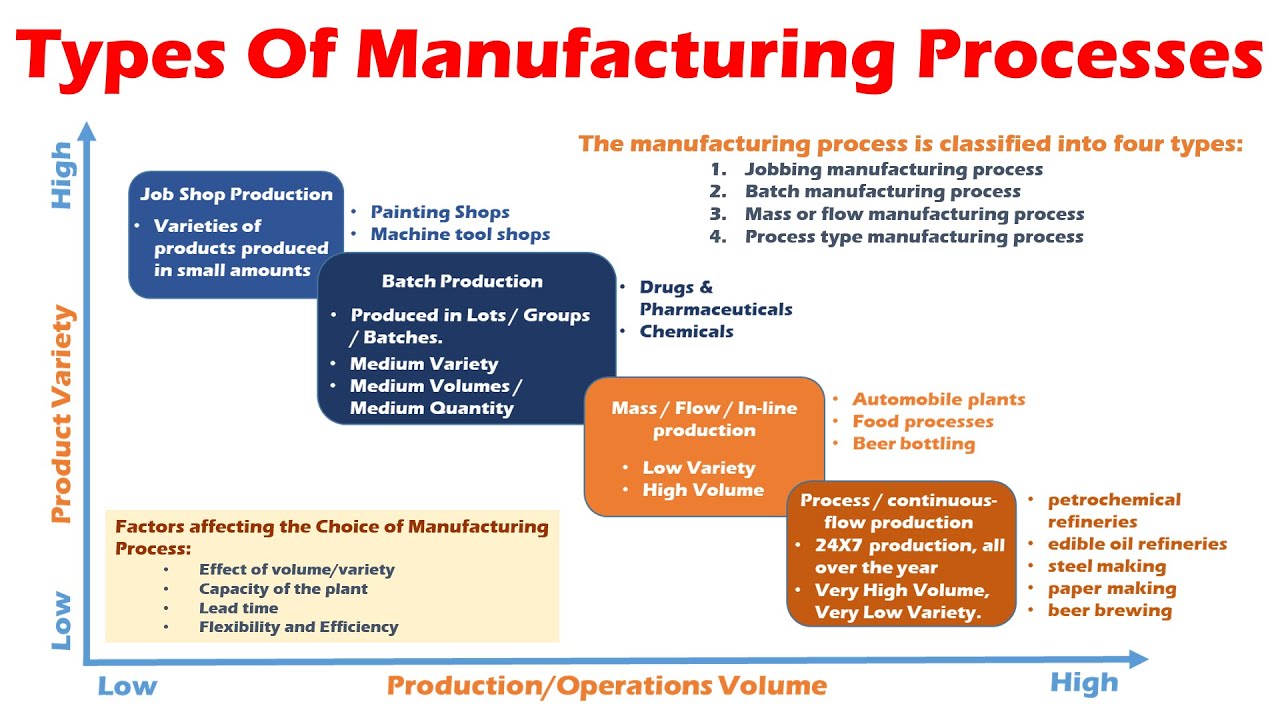

Here are four processes with different levels of automation: 1. 4 production processes categorized by amount of automationĪnother way to characterize a production process is to assess the amount of automation involved in the process. While you can measure the output or divide it into equal amounts, you can't take the soda apart upon creation. For example, a soda factory might combine different ingredients to make a hundred gallons of a soft drink every day. Typically, this manufacturing process creates compounds or formulas from ingredients. In process manufacturing, workers and machines create a product that can't divide into individual units or disassemble. Related: 6 Types of Manufacturing Processes 2. You can count the number of phones created, separate them into individual shipping boxes, or even disassemble one without affecting the others. At the end of each day, an assembly line might have produced hundreds of individual phones, each one ready for the next stage of the production process. For example, a plant that produces smartphones might have several assembly lines, where workers or machines combine the computer chips, receivers and other components of a smartphone. In discrete manufacturing, companies assemble discrete products, which are goods that you can quantify. Here are the differences between these two types: 1. The two main types of output processes are discrete and process manufacturing. One way to categorize a production process is to consider what type of product it creates. Related: Production Efficiency Formula: What It Is and Who Uses It 2 production processes categorized by output type Choosing the right type of production process can help a facility maintain production efficiency.

Manufacturing experts might categorize production processes by what they produce, how much they create or whether they use machines or manual labor. They might include different manufacturing techniques and processes, like 3D printing, joining or casting. Typically, a production process includes all the steps a facility might take to set production quotas, create and assemble products and distribute them to customers or third-party retailers. In manufacturing, production processes are different strategies that a manufacturing firm can take to create goods. Related: The Different Types of Manufacturing Environments and Jobs What are production processes in manufacturing? In this article, we explain what production processes are in manufacturing and provide information about several categories of production processes. If you're interested in a career in manufacturing or product development, learning about different types of manufacturing production processes can enhance your knowledge of the industry. Companies might manufacture industrial equipment, technological devices, toys, hygienic products or many other types of items. Manufacturing is a process that entails the creation of goods for consumer purchase.

0 kommentar(er)

0 kommentar(er)